Why Industrial Wax Products Are Essential in Modern Manufacturing

Industrial wax products such as paraffin wax, microcrystalline wax, and synthetic waxes play a crucial role in modern manufacturing by enhancing surface protection, lubrication, and production efficiency across various sectors including automotive, pharmaceuticals, packaging, and cable insulation. Their unique properties—such as thermal stability, water resistance, and adhesion—make them essential for high-performance processes. As demand grows for quality raw materials, bulk petroleum jelly suppliers like Noor Wax International Holding provide tailored wax and jelly solutions to meet the technical needs of global manufacturers, supported by decades of industry expertise.

In today's competitive manufacturing world, industrial materials like industrial wax products and petroleum jelly are vital to maintaining performance, quality, and efficiency. From automotive and pharmaceutical applications to packaging and cable manufacturing, these wax-based substances offer unmatched versatility and functionality across multiple sectors

What is Industrial Wax?

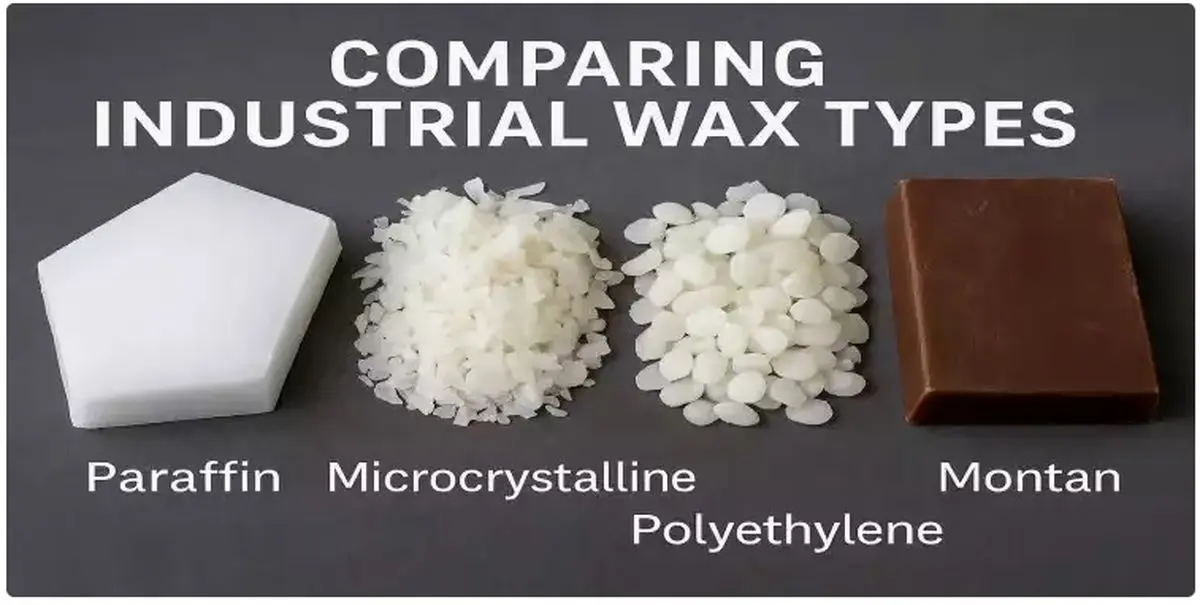

Industrial wax refers to a group of solid or semi-solid organic materials that are thermoplastic, water-resistant, and used for protection, lubrication, insulation, and surface treatment. These waxes can be derived from petroleum, plants, or synthetic sources. The most commonly used ones in industry include paraffin wax, microcrystalline wax, polyethylene wax, and synthetic waxes. Each type comes with its own melting point, flexibility, hardness, and compatibility with other industrial compounds

Main Types of Industrial Wax and Their Features

Among all options, paraffin wax stands out as one of the most popular choices. It is valued for its affordability, chemical stability, and ease of application. Paraffin wax is often used in casting, rubber processing, and packaging. Microcrystalline wax, on the other hand, offers better adhesion and flexibility, making it ideal for cosmetics, electronics, and pharmaceuticals. Polyethylene wax provides excellent abrasion resistance and is widely used in plastic processing, inks, and coatings. Synthetic waxes are custom-designed for specialized industries that demand consistent performance in high-stress environments

How Industrial Wax Enhances Production Efficiency

Industrial waxes contribute to efficient production by reducing friction, protecting surfaces from moisture, and enhancing mold release. In high-speed production lines, waxes play a key role in ensuring smoother operations and minimizing material damage. Additionally, they act as stabilizers in cosmetic and pharmaceutical products, improving shelf life and user experience

Applications Across Key Industries

:Industrial wax products are used in a wide range of sectors, such as

Automotive: polishes, protective coatings, and detailing compounds-

Cable manufacturing: gel compounds and insulation materials-

Pharmaceuticals and cosmetics: petroleum jelly and ointment bases-

Packaging: moisture-resistant coatings for paper and cardboard-

Rubber industry: processing aids and anti-ozonants-

Why Modern Production Lines Can't Ignore Wax Solutions

Today’s manufacturing environment demands quality, speed, and cost-efficiency. Industrial wax products provide these benefits quietly but effectively. They help manufacturers meet regulatory standards, improve product aesthetics, and protect goods throughout the supply chain. As industries evolve, waxes continue to adapt and find new roles in emerging technologies

Choosing the Right Wax for Your Needs

Selecting the ideal industrial wax depends on your product requirements, operating temperatures, safety regulations, and processing techniques. Leading bulk petroleum jelly suppliers and wax manufacturers offer customized solutions to meet specific industrial needs—ensuring consistent performance and material compatibility

Why Paraffin Wax Remains a Preferred Option

Paraffin wax remains a dominant choice due to its cost-effectiveness, widespread availability, and reliable physical properties. It offers great value for general manufacturing and continues to play an essential role in both traditional and advanced production processes

Partner with a Trusted Supplier – Noor Wax International Holding

If you are looking for a reliable product, with over three decades of experience, Noor Wax is a pioneer in the global production and distribution of white petrolatum (Vaseline), light liquid paraffin, paraffin wax and telecommunication cable compounds. The company proudly supplies high-quality jellies, oils and waxes to leading cosmetic and pharmaceutical manufacturers in over 50 countries in Africa, the Middle East, Latin America and Asia

.Contact Noor Wax today to request samples, technical data sheets, or bulk pricing tailored to your industry